In the diverse world of textiles, Nylon 6 POY serves as a remarkably adaptable foundation for products ranging from delicate lingerie to rugged industrial fabrics. What sets successful manufacturers apart is the ability to fine-tune yarn characteristics at the POY stage to meet very specific downstream performance requirements. This customization, when done correctly, can dramatically improve efficiency in texturing, knitting, and dyeing processes, while ensuring the final product performs exactly as intended in its end-use environment.

One of the key customization areas is denier, which determines the yarn's thickness and, ultimately, the weight and transparency of the final fabric. For fine garments like hosiery and underwear, low-denier Nylon 6 POY with excellent elongation and softness is critical. Meanwhile, heavier-denier variants are preferred in industrial textiles that demand higher strength and dimensional stability. Custom spinning setups allow precise control of these parameters, often requiring strict monitoring of polymer viscosity and spinneret configuration to maintain uniformity.

Shrinkage behavior is another important factor, especially in applications involving thermal processing. A lingerie manufacturer might seek Nylon 6 POY with controlled shrinkage to maintain shape and fit after dyeing and finishing. Conversely, in certain mesh or netting applications, higher shrinkage can be leveraged to create texture or elasticity. By adjusting the cooling rate and quenching airflow during production, these shrinkage properties can be tailored with impressive consistency—something experienced producers like us take pride in delivering.

Then there’s tenacity and elongation balance, which influence everything from fabric strength to stretch recovery. High-tenacity POY is often preferred in technical fabrics, where durability and resistance to deformation are paramount. On the other hand, applications like stretch knits may benefit more from a higher elongation-to-strength ratio to enhance wearer comfort. The key is understanding the intended use early in the production process, allowing for precise tuning of draw ratios and orientation during the spinning phase.

Luster, often overlooked, also plays a significant role in both aesthetics and function. Full-dull POY offers a matte finish suitable for elegant, high-end apparel, while bright yarns enhance sheen and are often favored in sportswear and decorative meshes. Customizing luster at the chip level or via additives during melt spinning ensures a consistent visual effect, which becomes even more important when fabrics must meet specific brand or customer expectations.

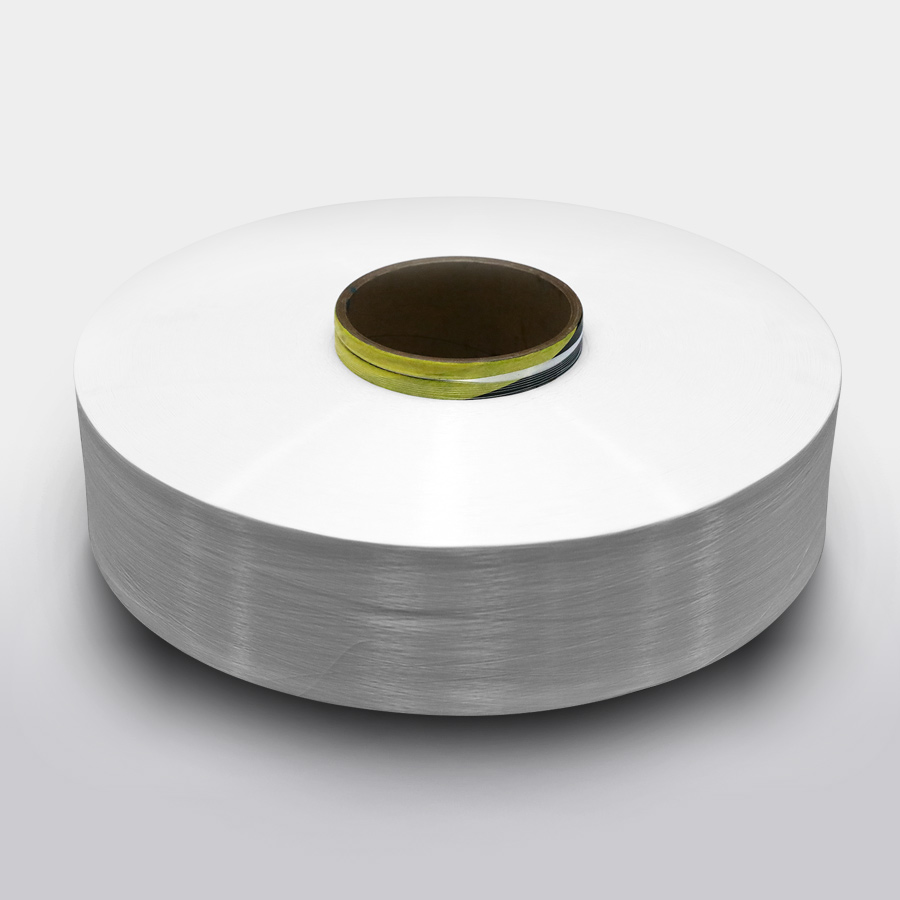

For buyers seeking a dependable supply of Nylon 6 POY with application-specific characteristics, working with a flexible, technically capable manufacturer is crucial. At Century Chenxing, we offer customized solutions for clients with unique processing requirements, whether they’re creating fine lingerie or producing mesh for agricultural or filtration use. Our production lines are built to adapt—supporting both standard and specialized POY configurations with short lead times and consistent quality.

In today’s textile industry, generic yarns can only take you so far. Tailored Nylon 6 POY not only enhances the value of the final product but also reduces waste and inefficiencies during manufacturing. By investing in precision and customization from the very beginning, you're setting the stage for smoother production and better fabric performance—because in a competitive market, the details matter more than ever.

English

English 中文简体

中文简体 Español

Español عربى

عربى